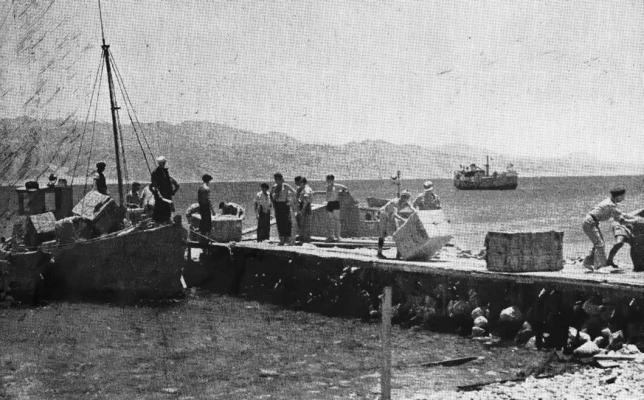

Lower Hold: Tallywoman at the Port of Eilat

I was between jobs in Jerusalem when the Yom Kippur War broke out in October 1973. After volunteering for a month I moved back home to Eilat, and went to say goodbye to former co-workers at a new luxury hotel. Walking into the once bright, cheerful, modern lobby I found a dark, echoing cavern - and was shocked to see the erstwhile general manager acting as caretaker.

In Eilat, a Jerusalem friend came to stay, and for a while we found work as movie extras. When filming ended in February 1974, I went to the local employment bureau. It was a novel experience because back then employers and employees found each other; jobs from the bureau were usually the lowest-paid or somehow undesirable.

The bureau was a small room with waiting area and a middle-aged, motherly woman sitting behind a desk. I was the only client. She confirmed there were no jobs in tourism and almost none to be had except, she hesitated, the Port Authority was looking for tallywomen to work evening shifts. She was taken aback when I said "'yes". Ports are notoriously rough, and it was no secret that many of Eilat's first citizens had been cons given a choice of going to jail or going to work in Eilat, and had found niches in the port. Was I sure? I was.

I was broke and hungry and needed a job, urgently.

That first shift, I was paired with a young woman who introduced me around and filled me in. With over half the port's manpower away on reserve military duty, and ships stacking up to unload, the administrative staff were working double shifts: office-work in the morning and on the wharf or in the goods-yard in the afternoon/evening. My mentor was the port manager's personal secretary-cum-tallywoman; her boss was doubling as a work foreman. That evening I was treated along with his colleagues to a spicy luff-shakshuka supper in his office. (Luff: tinned meat-loaf army rations, shakshuka: scrambled eggs with vegetables).

The manpower shortage was so acute that even retirees were rallying round. With two each of his many sons and grandsons already working there, the wizened patriarch of the Mizrachi family, spry in his 70s, sat hunched over the wheel of his small tractor, zipping strings of cargo flat-beds from dock-to-warehouse-and-back so fast, the stevedores and fork-lift drivers had a hard time keeping up.

What made the backlog so pressing, in addition to the war, was that, with the Suez Canal closed since 1967, much merchandise from Asia and Africa was trans-shipped via Israel, trucked from Eilat to Haifa or Ashdod Ports and thence by ship to Europe. In the other direction, Eilat's major export was phosphates in bulk, loaded at the southern end of the wharf and almost completely automated.

I learned the work quickly in the goods-yards and warehouses. Tallymen were assigned to a team of 6-8 stevedores, sometimes with a forklift and driver or more rarely a mobile crane and operator. At the start of each shift we received a work assignment and visa (documentation) from our team foreman to load a shipment onto a waiting truck; we would proceed to the location listed on the documents, deliver same to the warehouse manager to locate and log, and the truck would be loaded. It was the tallyman's job to keep track of cargo, documents and the time it took to execute the job. Once it was done, we hurried back to the foreman to get the next assignment, breaking only at 7pm for half-an-hour's subsidized dinner in the big dining room.

Every job has its own vocabulary: ours came with the Jewish stevedores of Salonika who manned the ports of a young Israel nearly 30 years earlier. It was a hazardous job. Varda! meant 'danger' and was usually shouted – and when it was, everyone moved somewhere else, fast.

Depending on the type of cargo and the time it took to load, a premium above basic salary might be earned for a speedy loading time. But premium ratios were hopelessly outdated because the types of cargo and handling methods had changed. For example, a work team could earn a premium on rolls or plates of sheet metal which were handled either by crane or fork-lift, while pallets with cartons or sacks or bales, needing more time and manual labor, earned little or nothing. Container shipping was just beginning, and in any case most cargos at that time came from small or medium-sized ports in Africa and Asia not yet equipped to handle them. We had everything from bales of carpets to paper sacks of cement, and walking past the locker of Warehouse #3, where sacks of spices were secured, was a heady experience indeed.

In fact, there was quite a disparity between visual and olfactory input. Surrounded by tan desert roofed in blue sky, blue sea to one side, the port was almost monochrome in shades of grey cement, cinder block, asbestos and pavement, with some cardboard and burlap browns. By contrast, it was the aromas and smells that emphasized where we were and what we were doing.

For three months, I roamed the goods-yard with the work teams as winter morphed into spring, eating dinner with them in the dining room or exchanging a meal ticket at the commissary for a yogurt and pack of cigarettes. The salary was excellent and I managed to pay my overdue bills.

The cold desert wind could bite and embed dust and grit in clothing and hair, and once my woolen gloves became impregnated with cement from a late-night shipment: the importer had waited months to pick up the consignment and it had been rained on, turning the sacks into lumps almost impossible to load.

The stevedores were mostly a pleasure to work with, from many different backgrounds and almost as many countries. They quickly learned that I wasn't phased by cussing or bad language; for some it was the only language they knew, so 'intent' was more important than 'content'. Also, I took my job seriously. Nor did they come on to me or make passes. A couple of family men did try to charm my pants off and a nice young man was looking for a wife, but I wasn't interested. The environment itself was hazard enough without entanglements: a steel plate once dropped behind me with a terrifying thunk; I was almost run over by a truck; a long nail just missed passing through my foot, and once I tripped over my own purse-strap – which was the only time they heard me cuss. During rare lulls we would sit around talking and telling jokes and one glorious evening, lounging on sacks of beans, I listened to a political science discussion that would have done credit to any university.

Out in the wind, even in winter, we had to drink enough water to stay hydrated; we were always supplied with a cold jerrycan because "no water" was a legitimate reason for work stoppage. Once, in summer, the entire port ground to a halt for nearly half-an-hour when the fork-lift driver with the 10-jerrycan rack didn't show. (Rumor had it there was a hot poker game in one of the warehouses.)

The only person I actively disliked/distrusted was an ex-pimp. On the other hand, two managers I liked and respected had an interesting back-story: they had been cat-burglers until one was caught and received a longer sentence for refusing to name his accomplice. His partner waited for him to get out of prison to split the proceeds of their last heist, then they started over in Eilat and made successful careers at the port. And Marion (an ex-embezzler) who was a tallywoman for Sherutei Menayah ('tally services') became a very good friend.

More and more men were being released from the army and one day I was told my services were no longer needed. I begged to stay on, which is when I learned why the Port Authority only hired men for permanent employment: of a group of twenty women once hired to work as tallymen only three remained. One married a stevedore, was a mother of three and refused to work evenings; the second was promoted to the offices; and the third had great notoriety among truck drivers.

There was another option, however. A foreman introduced me to Ben Shimon, the office manager of Sherutei Menayah, which did the tally work for Dizengoff Shipping Agency. I was hired on the spot. The pay was not as good and it didn't come with meals, but I'd still be in the port and could work either morning or evening shift – or sometimes both.

This was a different kind of tallywork, on the wharf. Two tallymen, representing the Port Authority and Sherutei Menayah, were assigned to each ship's hold and had to keep track of everything being unloaded. We worked mostly on the quayside, waiting for each pallet to swing down over the ship's side. If we were lucky there was a shady spot to sit on the crane's base between pallets; if not, we stood out in the sun or sometimes in a hot, dark ship's hold, scrambling to write everything down before the pallets were whisked out of sight.

Each tallyman was supposed to work independently but often it was impossible: cargos were moved so fast that we barely kept track of the 'marks' (3-letter shipping addresses) for each consignment; we compared notes at the end of the shift to make up our tallies. We were aided by the fact that cartons and sacks were always loaded the same way: two across end-to-end with three-in-a-row, the next layer the opposite, three-in-a-row and two end-to-end, creating a binding effect allowing 3, 4 or 5 layers of cargo per pallet, 5 items per layer.

We worked inside the holds as needed: U/H – upper hold, T/D – 'tween decks, L – locker and L/H – lower hold. The notations on our work roster were always in Latin, so "4T/D & L" translated to "No. 4 hold 'tween deck and locker". The levels of each hold were separated by movable steel beams crossing the width of the hold, across which were laid metal-bound wooden floor-boards to create the floor of each level, similar to hatch covers.

I soon had opportunities to work upper holds and 'tween decks, but everyone said I would not qualify until I'd worked a lower hold. Marion especially cautioned me: the first time she'd worked LH one of the stevedores jokingly told her "there's a rat". The next thing she knew she was on deck. No one could figure out how she made the two-story climb so fast – hence her nickname "the flying tallywoman".

The ships were as varied as their origins, crews and cargos. The cleanest and best maintained was a Korean owned and crewed vessel, shipping sealed boxes of charcoal dust - which I got liberally dusted with. The most amazing was a small Liberty ship with three holds and bridge at the stern; it was so well maintained that it unloaded its cargo using its own winches, and people took time out to get a closer look at it. Another time, stevedores pocketed pieces of a brown root with a bright yellow core that fell to the ground from sacks; they told me it was an ingredient in Coca Cola and took it home for their kids to chew on. I tried one and it had a sweetish taste.

Then there was the time we had to inventory a container leaking strong smelling, sticky liquid. It turned out to be a consignment of wines and spirits from Greece to a Greek diplomatic mission in Africa, and some of the cases had broken open in transit. Unfortunately, the container was opened away from the prevailing wind and the fumes were so strong it made us dizzy: it was all we could do to finish that shift on our feet... and none of us had drunk one drop of alcohol!

By far the worst experience was a shift spent downwind of a copra ship. It stank, baaad. Copra is the dehydrated kernel and/or husk of the coconut which has uses in human foods, cosmetics and animal fodder. Morris, an ex-Aussie port tallyman, took three showers when he got home and it was days before his sense of smell came back.

After two months, I saw my name followed by "Marianna: 1L/H, finish". Ben Shimon was pleased for me as it would be my first lower hold and "finish" meant we could go home early when the hold was empty. Since there was a bus into town at 19:15, we might even get home in time to watch the evening news and catch the basketball game scheduled for that night. I joined the stevedores on the way across the goods yards. We were optimistic until we got to the wharf.

The almost empty ship was riding high so we had a steep climb to the deck. Then we saw that the four heavy wharf cranes, on rails, were already in use elsewhere. So where was ours? It came lumbering around the corner of the warehouse - two-and-a-half stories high, it was the oldest crane in the port and the only mobile tall enough – barely - to reach over the deck once it's four jacks were set.

And the operator was a fork-lift driver for ten years who had just qualified as a crane operator three weeks earlier

As we climbed down the recessed metal ladders into the hold, assailed as always by the smells of seawater, oil and bilge. #1 hold was in the ship's prow: from the inside it looked like something out of the Poseidon Adventure or an up-side-down gothic cathedral (minus statues), the effect enhanced by a dark brown pebbling that covered everything except the loose, mixed cargo.

Work got under way smoothly enough, though the crane's lifts were sometimes a little jerky. Then we began hearing slapping noises against the hull, and a little later the ship began pitching from stern to bow. The Red Sea at the head of the Gulf is usually flat as a pancake, with or without a ripple created by the prevailing north wind. The ship's movements meant a rare south wind had come up, creating a swell.

The sky had darkened to dusk, then I noticed the silhouette of the commando (signalman) had changed –because our commando was seasick!

The pallets used in the port were made of wood, with metal corners and two recessed edges. The corners had holes in them for hooks to be attached to lift the pallets, but these were never used; it took too long to hook and un-hook them. Instead, two flexible steel cables called 'virerim' (wire+pl.im), with loops on the ends, were used. Two stevedores ran the cables under the two recessed edges, hooked the loops over the crane's hook, then held the cables in place until the slack was taken up and the pallet lifted.

All stevedores were well versed in the technique and usually stepped away from pallets with ease. But as the swells got stronger and the almost empty ship rose and fell more steeply the pallets began lifting erratically, swinging unpredictably this way or that before soaring high enough above our heads not to be an immediate danger. Now the stevedores were actually springing away from pallets, and by the time we were down to the floor boards everyone was heading for the farthest corner they could reach as each pallet rose. Then the crane's boom hit the side of the hatch, and the dark brown pebbling showering down on us turned out to be rust.

As the hold emptied the wedge-shaped floor space shrank. We were down to the last four loads when I stepped aside to finish up my tally on a convenient stack of cartons. Behind me someone yelled "Varda!" and I whirled to see a loaded pallet swinging straight for my head. There was nowhere else to go: I bent double, dove under the pallet and came out the other side running ... by which time it was high overhead.

Mine was the closest of many close calls that shift. Five minutes later we were up the ladders and making tracks, just in time to catch the bus to town. Next day I told Ben Shimon and my colleagues what an "easy" shift I'd had. They were sceptical but the other tallyman and stevedores bore me out; what was supposed to have been an easy shift had turned into one of the hairiest most of them could remember.

After three more months I got tired of sitting in one spot all the time. Tourism was finally picking up, so I went back to hotel business - my first love. Years later, on a daily commute past the Port, I would look for that crane standing idle near the port's north gate.

It had become a pigeon roost.

Afterword: I had a wonderful time as a tallywoman. I gained great experience and insight as well as another perspective on what the Israeli melting-pot was/is - and met some very good and kind people.

Comments